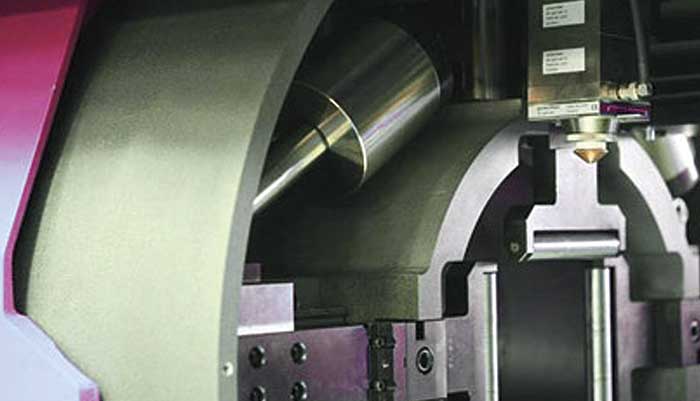

Tube Lasers Cutting Systems Houston Tx

With Lasertube systems, you can create new applications or improve existing ones, entering new industrial sectors and increasing profit margins.

Laser technology can be used to create custom shapes and make them cut to length. Raw material is used to produce finished or semi-finished products.